TG-4 Machine Specifications

| Tool data |

| Max. workpiece length |

400 mm |

| Max. workpiece diameter |

Ø 200 mm |

| Grinding Spindle Drive |

| Spindle speed |

1000 rpm~6000 rpm |

| Peak Power |

5.5kw (7.5HP) |

| Spindle taper |

BT-50 |

| Resolution |

0.001° |

| Mechanical Axes |

| X Axis |

370 mm |

| Y Axis |

230 mm |

| Z Axis |

170 mm |

| C Axis |

360° |

| Rapid traverse X,Y,Z |

6000 mm /min |

| Axis Motor and Coolant System |

| X axis servo motor |

1 kw |

| Y axis servo motor |

1 kw |

| Z axis servo motor |

1 kw |

| C axis servo motor |

1 kw |

| Coolant |

2HP & 2HP |

| Lubrication |

25 W |

| Controller |

| Model |

MITSUBISHI |

| Machine |

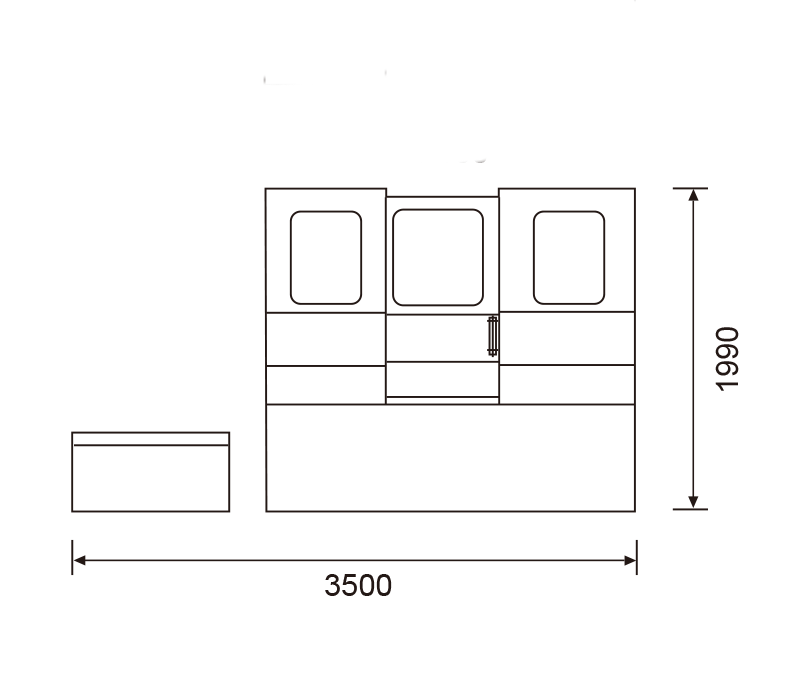

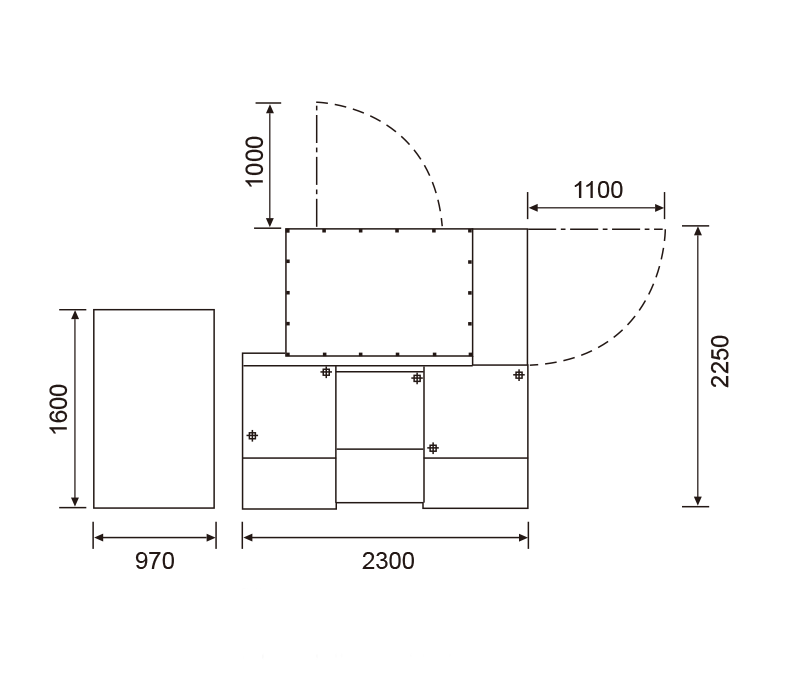

| Floor space |

3200 x 2300 x 2250 mm |

| Weight |

4530 kg |