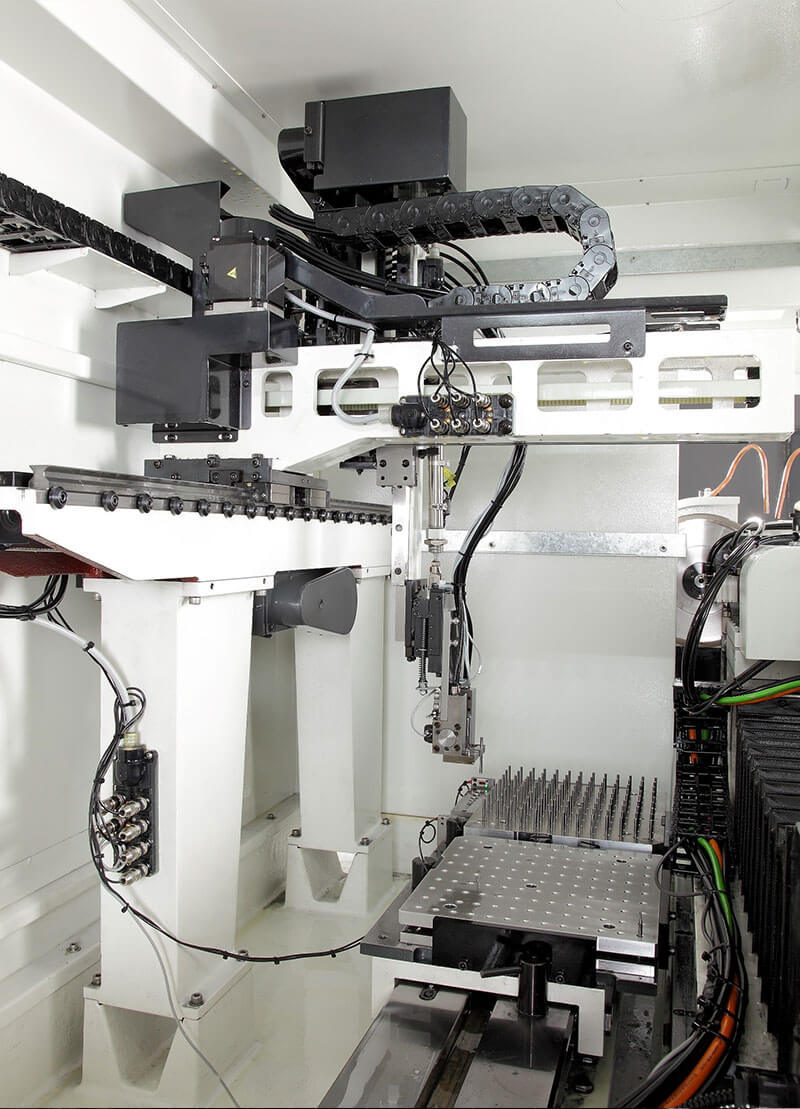

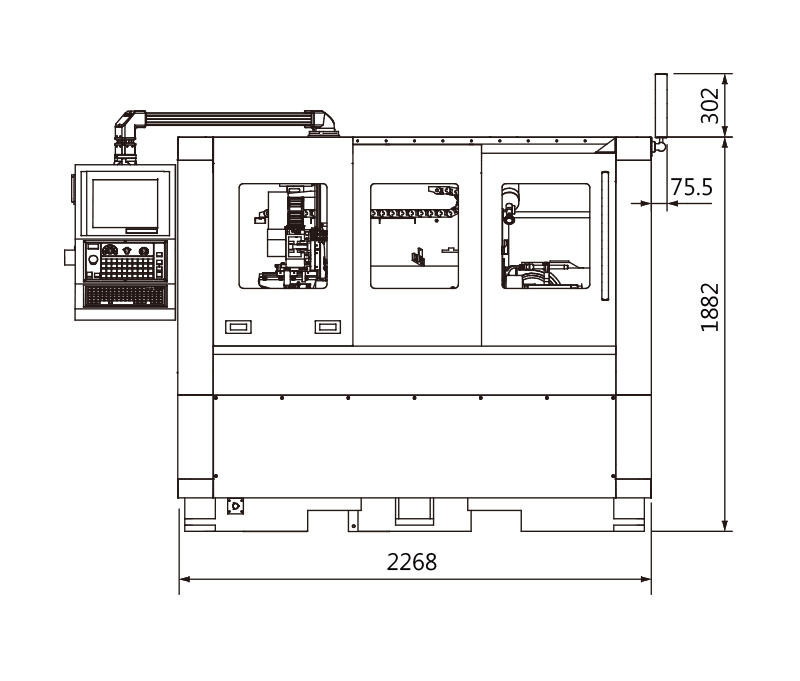

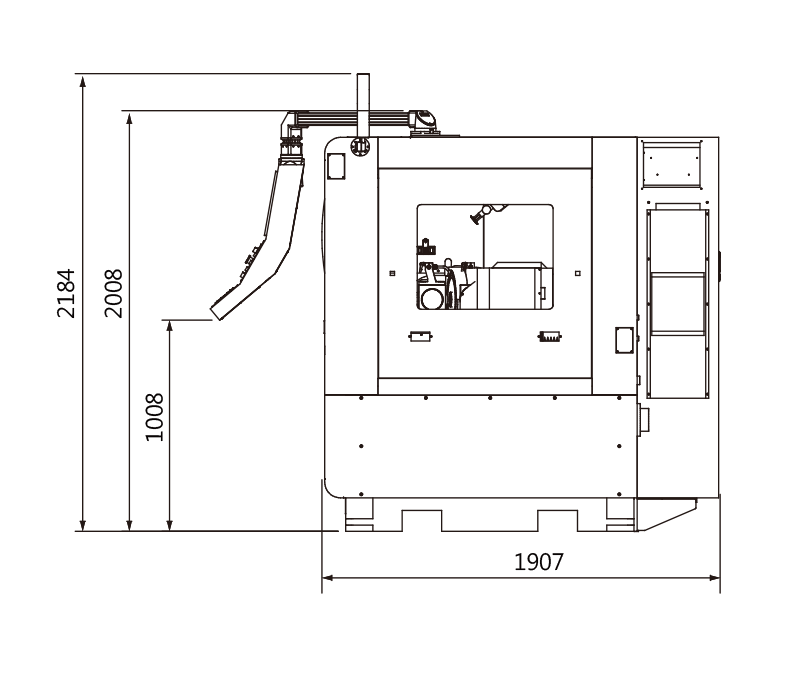

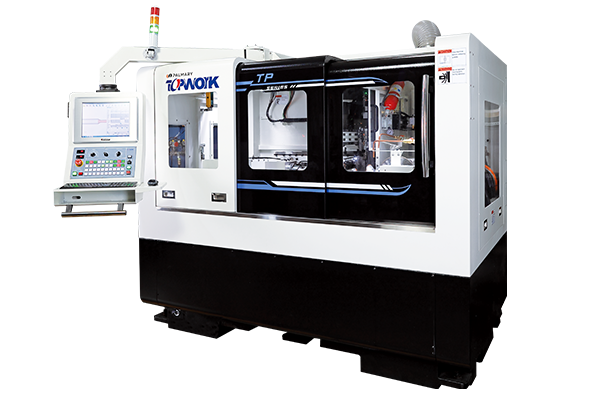

TP-4 Precision Cylindrical PINCH/PEEL Grinder

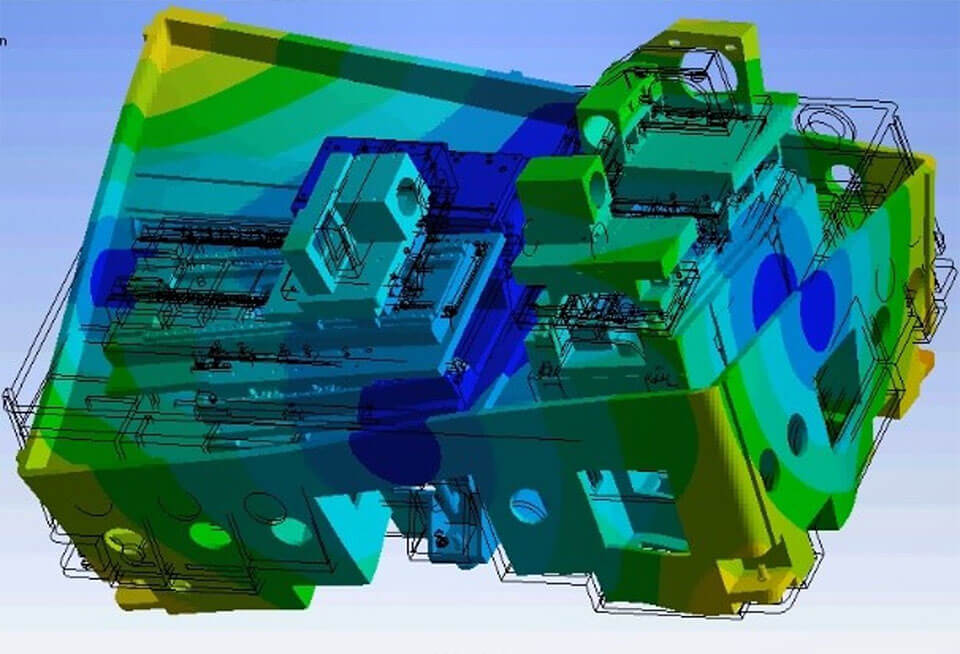

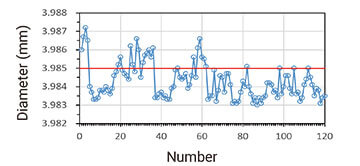

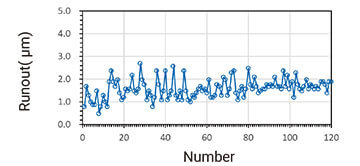

Unparalleled Precision and High Stability

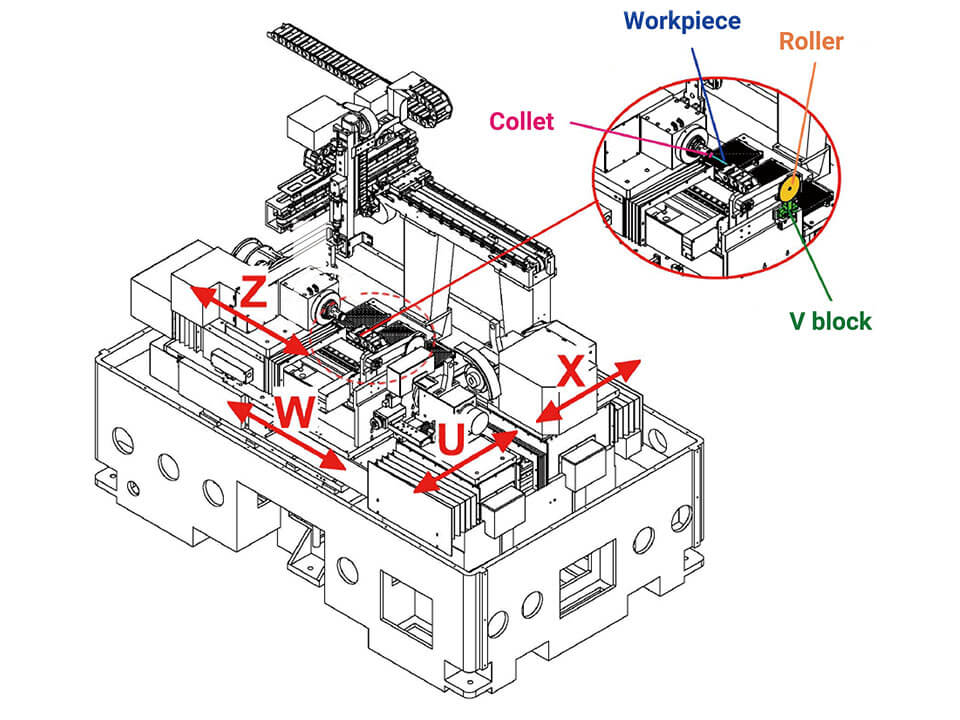

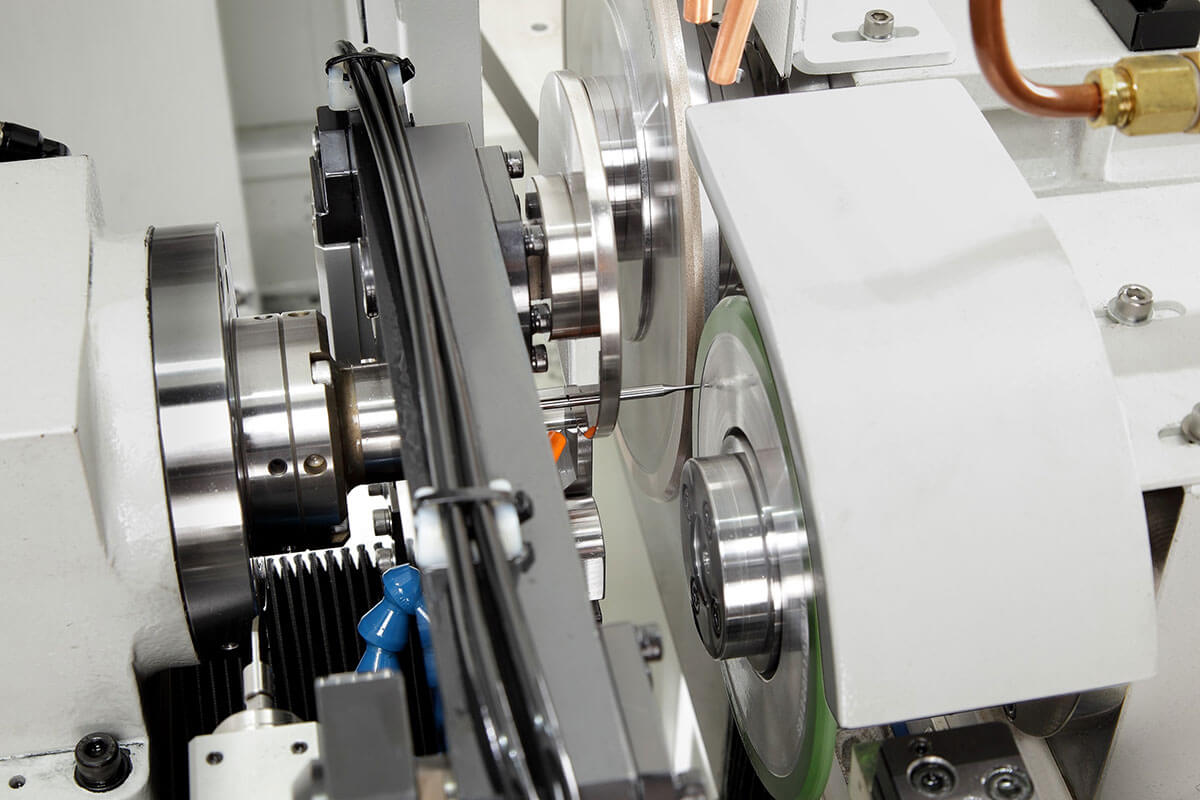

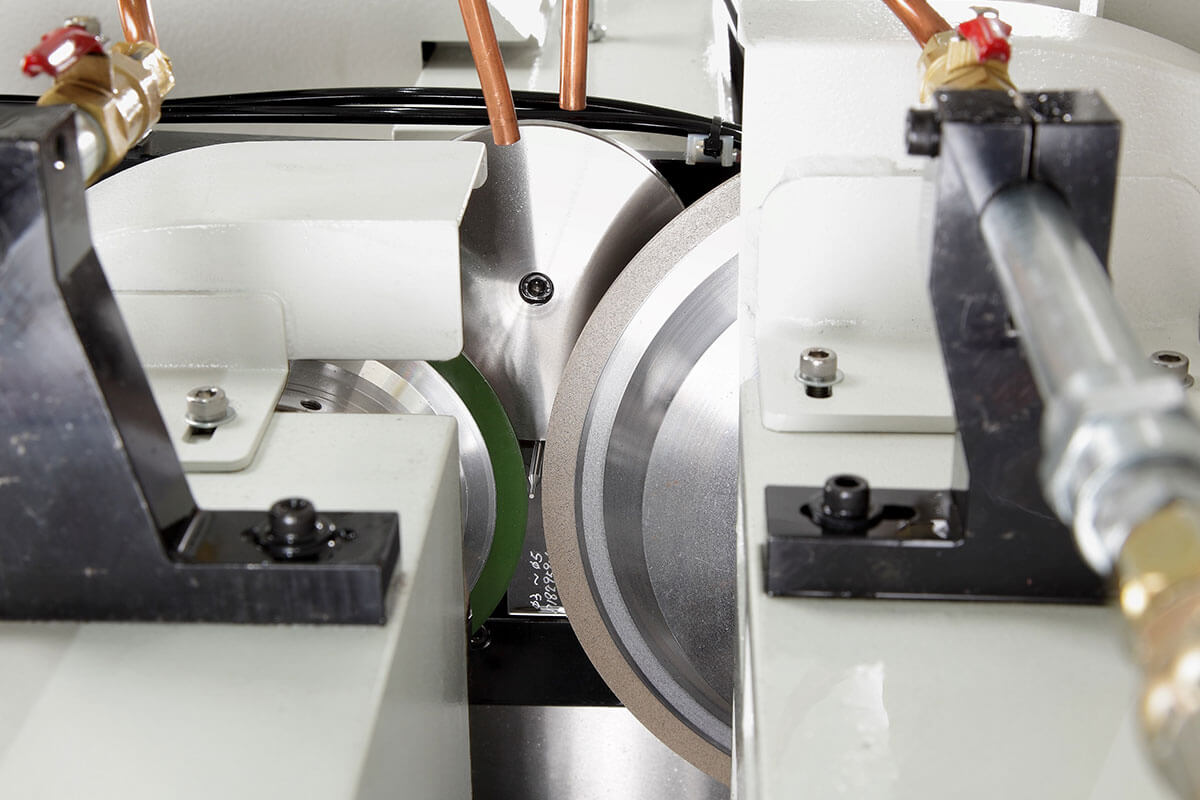

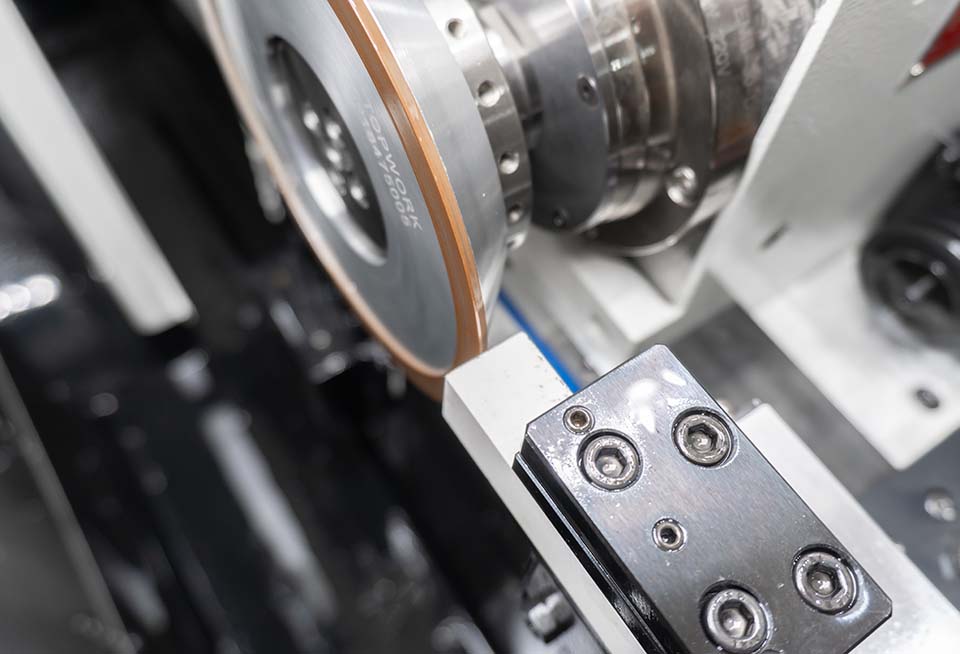

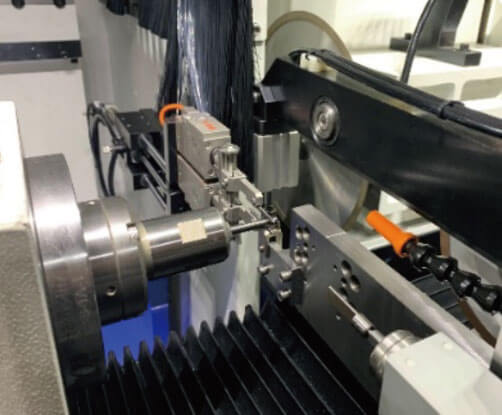

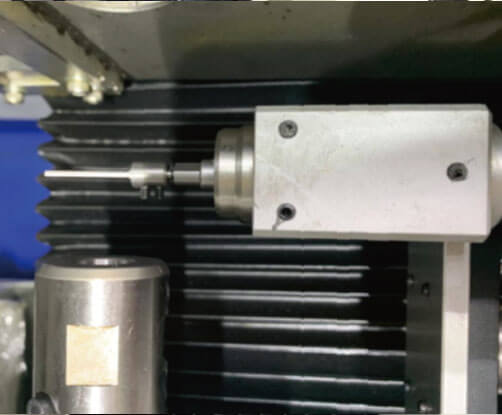

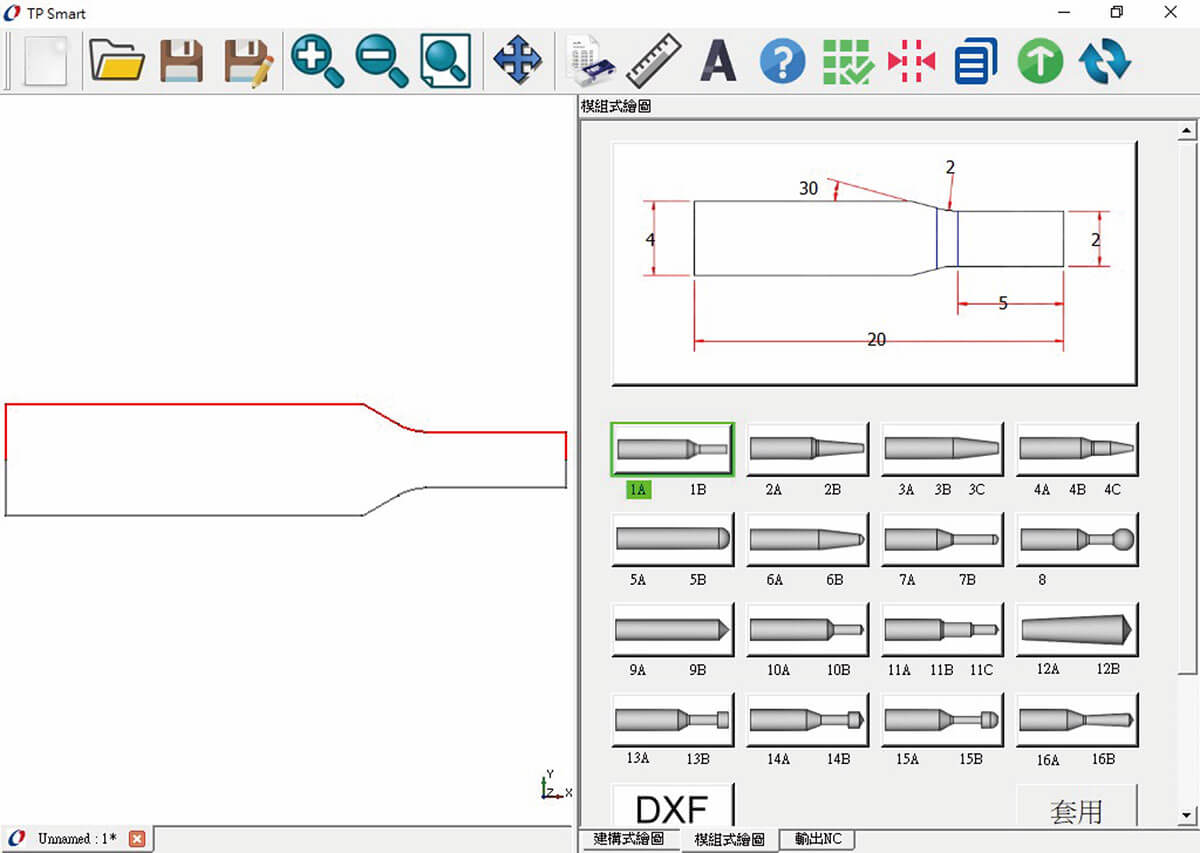

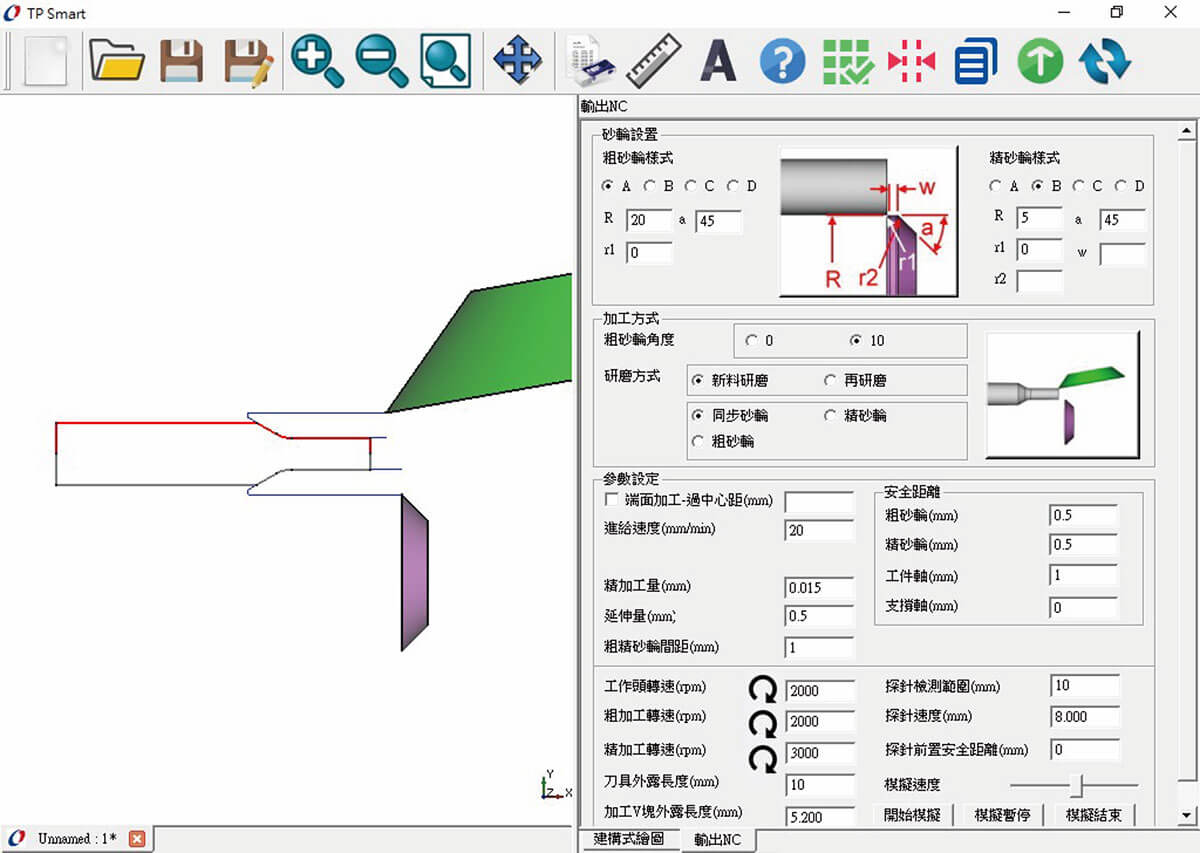

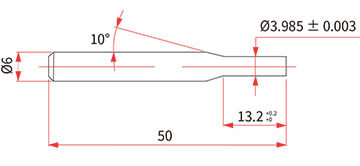

TP-4 is a smart tech high precision CNC cylindrical pinch/peel grinder with two grinding wheels operating simultaneously for grinding cylindrical materials of cutting tools and form punches. This model is used after doing centerless grinding and before doing the pre-process work on 5-axix tool grinder. It has applied to various industries, mainly used in high-precision tool industry, mold industry, and electronic and medical parts industry.

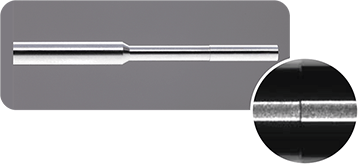

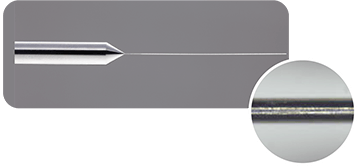

TP-4 Can meet all your application needs for grinding carbide and endmill, drill and form blanks.

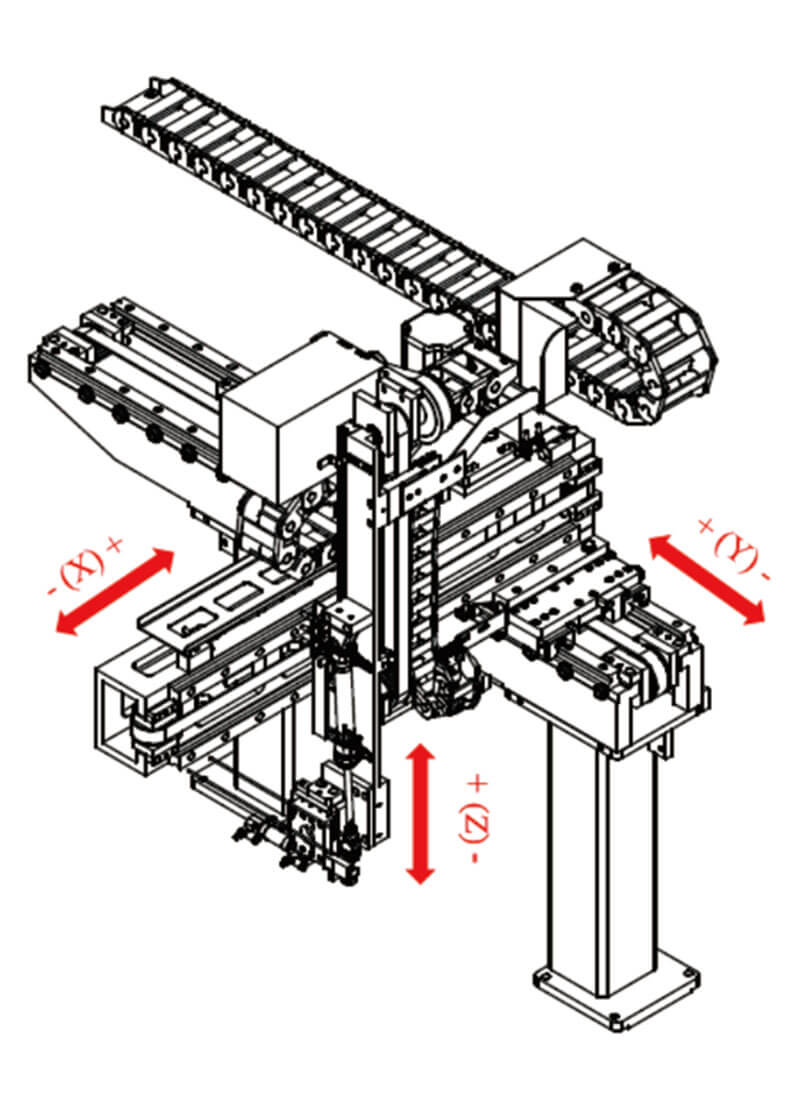

The machine follows ISO 230-2 and we ensure the repeated positioning accuracy (R) is as low as 2 µm and the positioning accuracy (A) is 4 µm. The cutting tool blanks cover a range from diameter 0.1 to 20 mm. The maximal grinding length is 330 mm and the length/diameter ratio is up to 350x D.