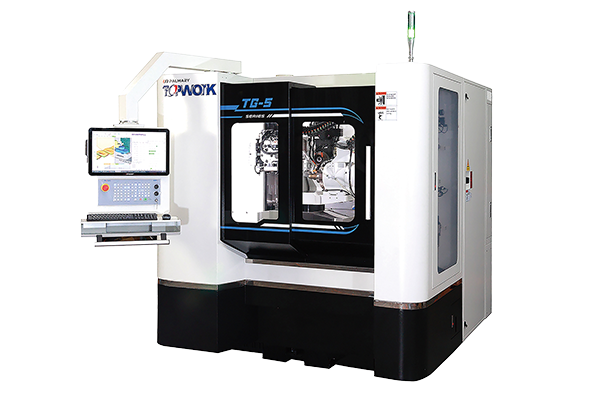

TG-5 CNC Tool & Cutter Grinder

Accuracy Rigidity Efficiency

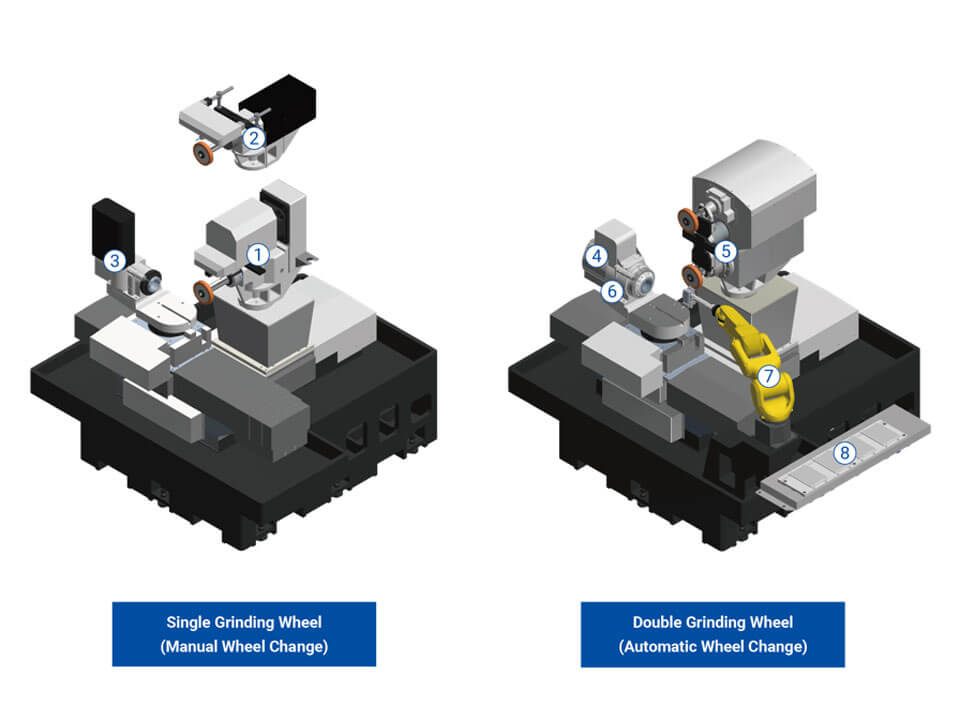

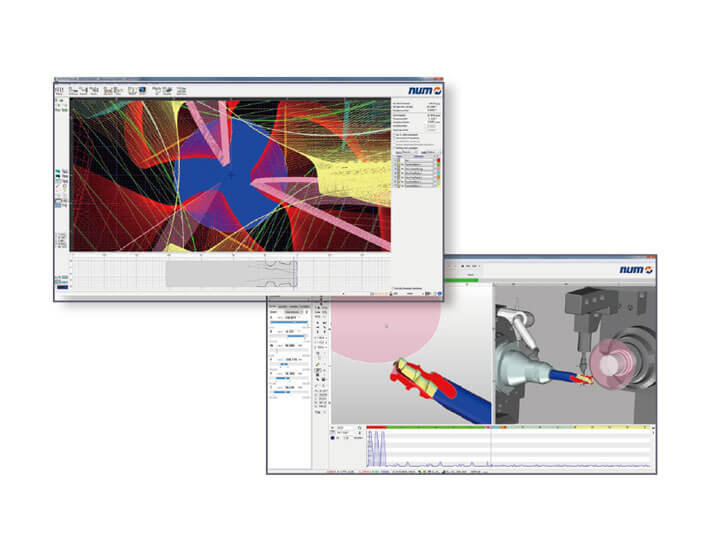

The TG-5 CNC tool grinder is flexible, precise, and economical. Its cost-effectiveness with the world famous NUM Flexium+ 68 controller and NUMROTOplus® software features versatile functions, for instance, excellent tool designs, 3D simulation, and collision monitoring.

5-axis simultaneous motion design achieves 0.1 μm precision, and efficiently handles various types of grinding technical problems while in operation. It is the best solution to meet your needs and realise an intelligent production system in the era of industry 4.0.