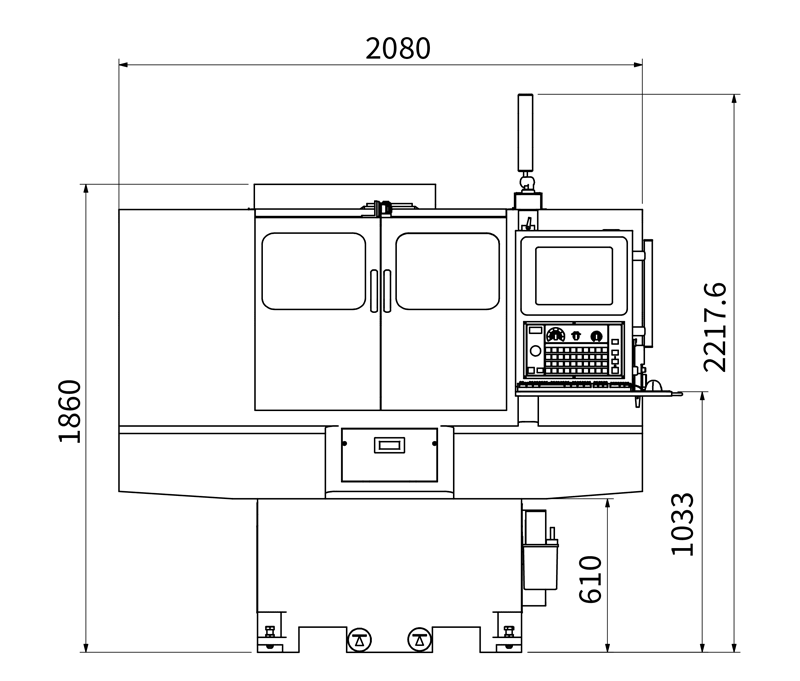

PTG-32 CNC Punch Grinder ※Patent Pending

Accuracy Rigidity Efficiency

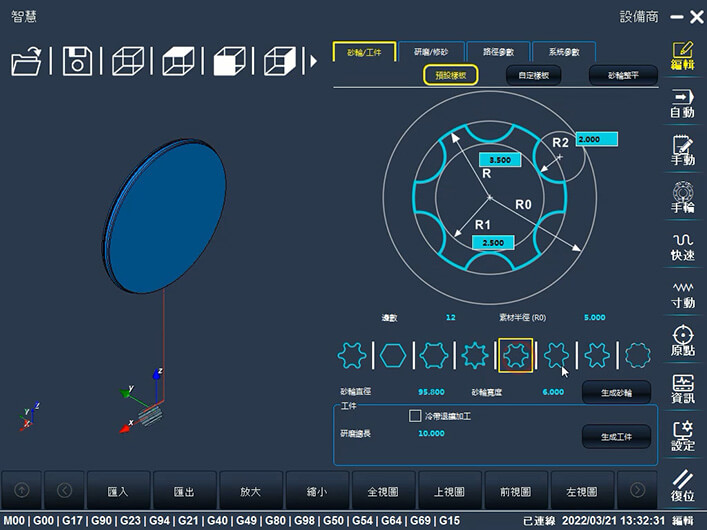

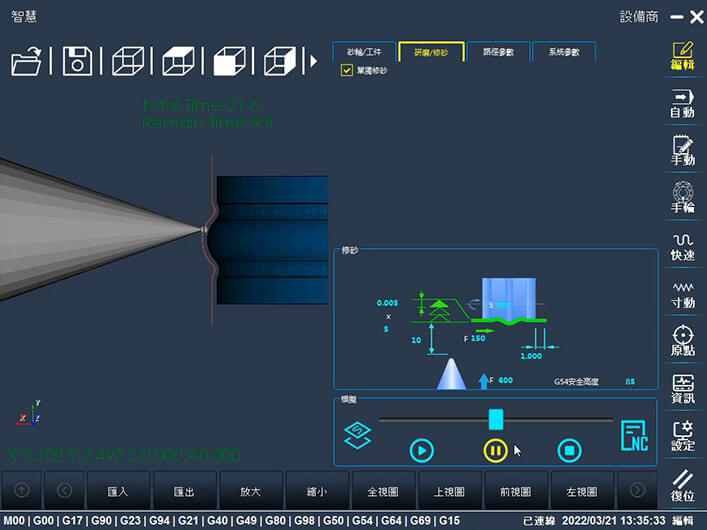

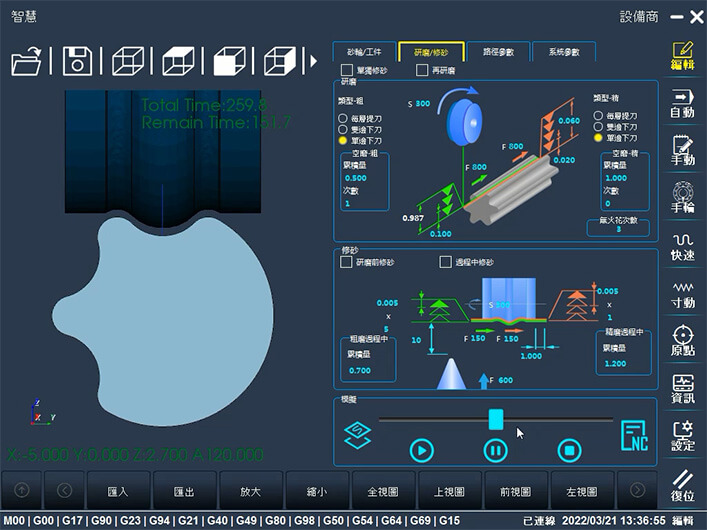

Equipped with a Delta OPEN CNC controller and Topwork-developed HMI, PunchSmart software delivers intuitive operation and versatile punch grinding solutions.

7 Built-in punch modules – easy to set up and customize

Auto path generation & simulation – precise, collision-free grinding

One-cycle grinding & in-process dressing with auto compensation for high efficiency and accuracy