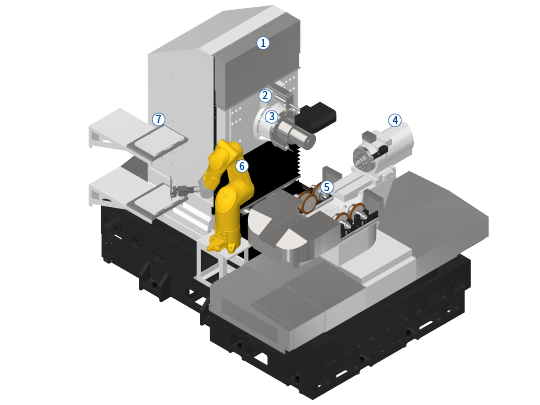

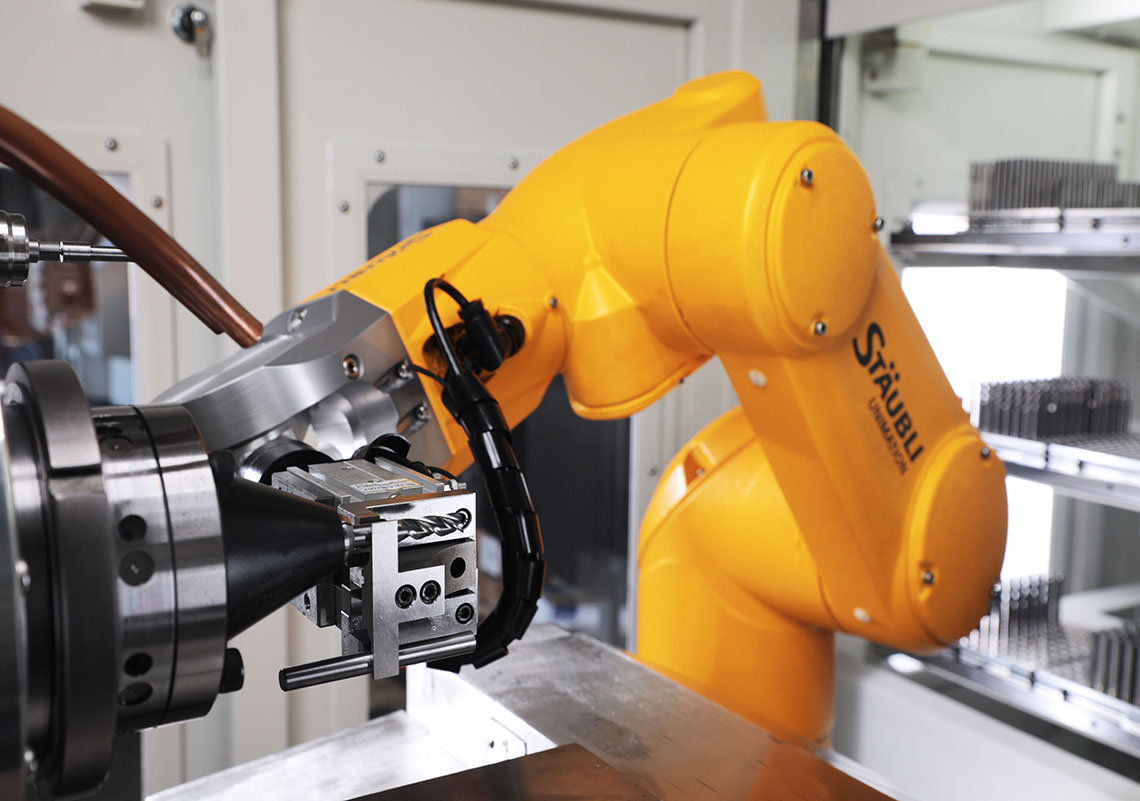

TA-5 CNC Tool & Cutter Grinder

Accuracy Rigidity Efficiency

The TA-5 CNC tool grinder features highly rigid structural design and is aimed at grinding medium-sized and large-sized HSS and carbide material, especially at applications of aerospace and automobile.

It is widely used for standard tools, special tools, re-grinding, batch grinding, and mixed batch grinding, etc. high power output spindle and unmanned operation, while it remains stability and precision during the grinding process.